M70 Upper pan gasket replacement-

This can be a fairly easy job if you ignore the book procedure, which calls for pulling the trans and then removing the pan out the back. That also requires pulling the oil pump and probably lifting the engine. The easier way is to drop the entire front sub-frame. Then the pan drops straight down and the oil pump doesn't need removal. I have a lift, but this can be done on the ground well enough. One man job. Here's the short list of tasks involved. I've probably overlooked some, but it's an intuitive and uncomplicated job with little leftover hardware.

In a nutshell:

Get the front of the car up on stands. Gerry_UK's are the superior arrangement, see archives

Front wheels off

Remove the sway bar

Drop the center link off the pitman arm and idler

Unbolt upper and lower control arms, at which point you need to block the struts up just to hold them out of the way

Remove the tubular (or cross brace) rear crossmember. You might be able to skip a step here if the sway bar can come off with the crossmember, I forget if it's possible

Unbolt bottom of motor mounts

Get a jack under the trans, lift it 1/4" or so and get a jack stand in place. A block of wood doesn't hurt. You don't want to lift much, just enough to carry the load of the motor on the tranny for a short while. If you're a belt and suspenders kind of guy like me, rig a sling for the motor BEFORE you figure out about the jack under the bell housing. The sling was a good backup in my case; the jack under the trans leaked down overnight. Use a jack stand and you don't need a sling.

Take snorkel off alternator

Remove fan and lower belt

Power steering pump bolts to pan

Steering box mounts to crossmember- The hardest part of that job is the bolt and nut that runs longitudinally. The nut is on the forward end in a difficult area. Off is OK, back on takes a magnet-on-a-stick tool to hold the nut in place while trying to thread the bolt.

There are 3 long bolts on each side of the crossmember. The ones at the rear go thru a locating dowel into the chassis rails. The dowels are VERY snug and will probably need a 3-foot persuader to pry the crossmember out.

The dipstick tube is held in place with a clip and bolt on the top side of the pan. There's an o-ring there that should be inspected. You can unbolt the top of the tube, too, and remove from pan from the top side. You'll avoid binding while trying to lower the pan that way.

There are 4 M6 bolts on the torque converter (rear) side of the pan, out of sight. You can access the middle two thru the center hole with a rubber cap in it. To get the 2 outboard ones, you need to mutilate the pan a bit, tho not as much as I did. A notch cut out of the lower portion of the buttressing web cast into the pan is adequate. I would make a 3/4" cut horizontal and vertical to leave a "square" opening big enough to get a 10mm socket thru. That's easier that trying to drill a 3/4" hole, tho either way works fine. I used the smallest hole saw I could find, on a Milwaukee Hole-Hog, when I did my first car, and it was a bit cruder than planned. No harm done, but not pretty. You can plug the holes up afterward, but there is also no down side to leaving them open. The plastic grate on the bottom of the trans bell leaves everything open to the elements anyway.

Drain the oil. It will drip for days with the pan off, so a mortar pan is handy.

Put the 9th Symphony on the stereo and begin removing pan bolts. You'll finish by the Ode to Joy, maybe.

There are 3 lengths of M6 pan bolts IIRC

It is necessary to unbolt the oil collector tube from the rear of the oil pump. The pump can stay in place.

There are some male Torx head bolts connecting the UP to the trans, for which you need the right socket

Bloogoo the gaskets liberally, and pray that the new ones are better than the originals.

Great time to clean up the lower engine compartment, but not a lot of other opportunities for mission creep on this job. Unless your steering box is marginal, or you need motor mounts, or your Kbars have arrived, or the ball joint boots are cracked…

The superfluous motor sling

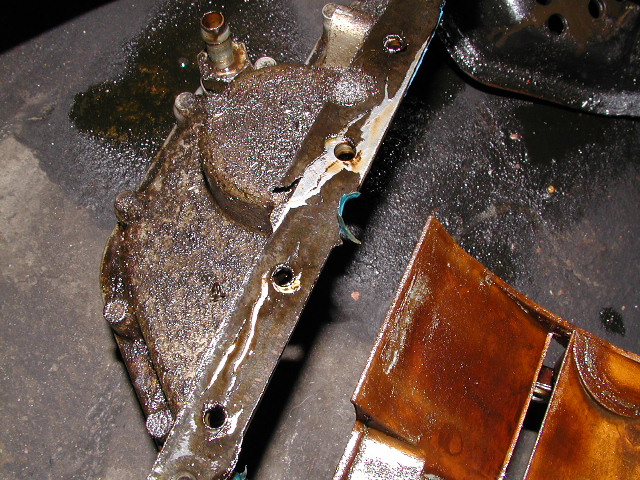

14 year old pan gasket

Dipstick tube mount and o-ring on right top side of pan

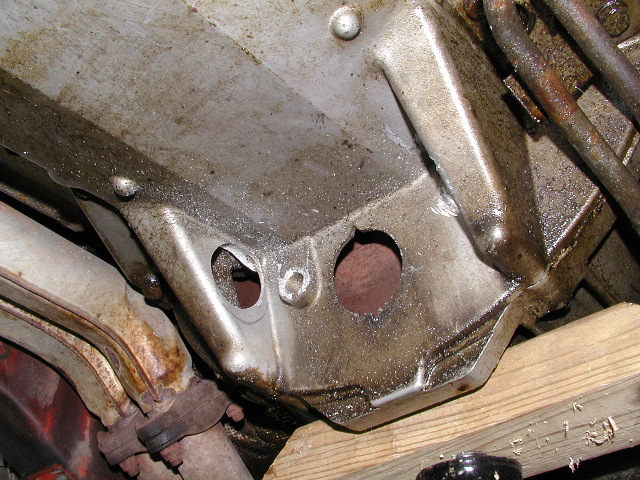

Crossmember removed- note tubular dowels at rear

End of the disassembly phase; oil pump removed for clarity, but not necessary

The crude but effective approach

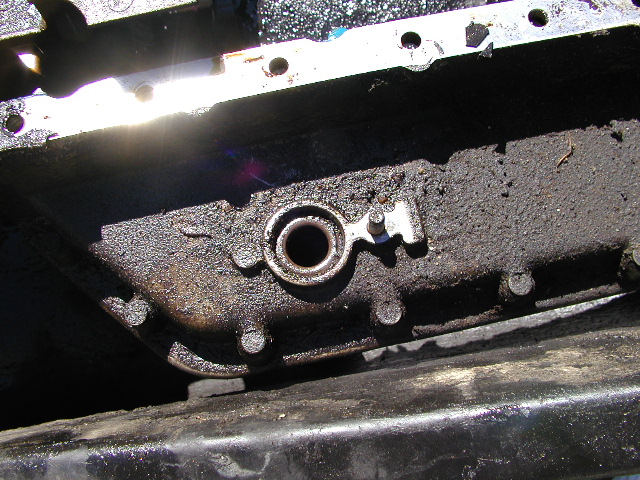

The four hidden bolt holes on the back side. You can see all 4 from the existing center hole, but

the outboard ones would be almost impossible to re-insert